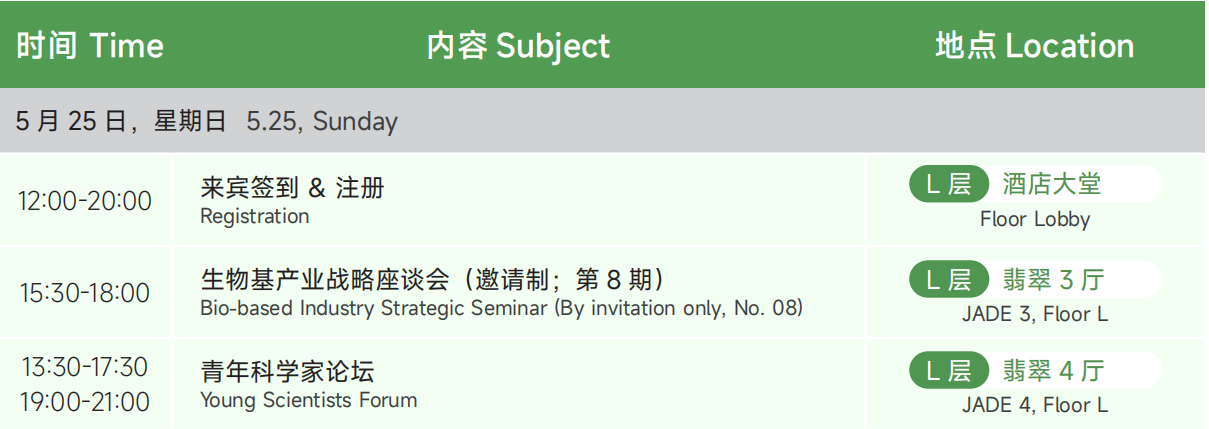

【已举办】2025(第10届)生物基大会暨展览 (Bio-based 2025)

-

2025年05月25日-27日

时间

-

中国 · 上海余山茂御臻品之选酒店

地点

-

向绿而行,向新求质

主题

论坛背景

第十届生物基大会暨展览(简称 Bio-based 2025) 将于5月25-27日·上海佘山茂御臻品之选酒店举办,由 4 位院士领衔100+企业高层和顶尖专家,为生物基行业的下一个拾年“把脉问诊”。活动以“行业大会、创新展览、新叶奖评选与颁奖”三大板块同期进行,共设置1场评选、5大论坛、17大专场、4大特色对接&交流会,预计将超过 1500+ 行业同仁出席。

向绿而行,向新而质。第十届生物基大会立足全球视野和下游用户需求,加速科技创新与产业创新融合发展,助力行业上下游企业迈向新征程。

展会架构

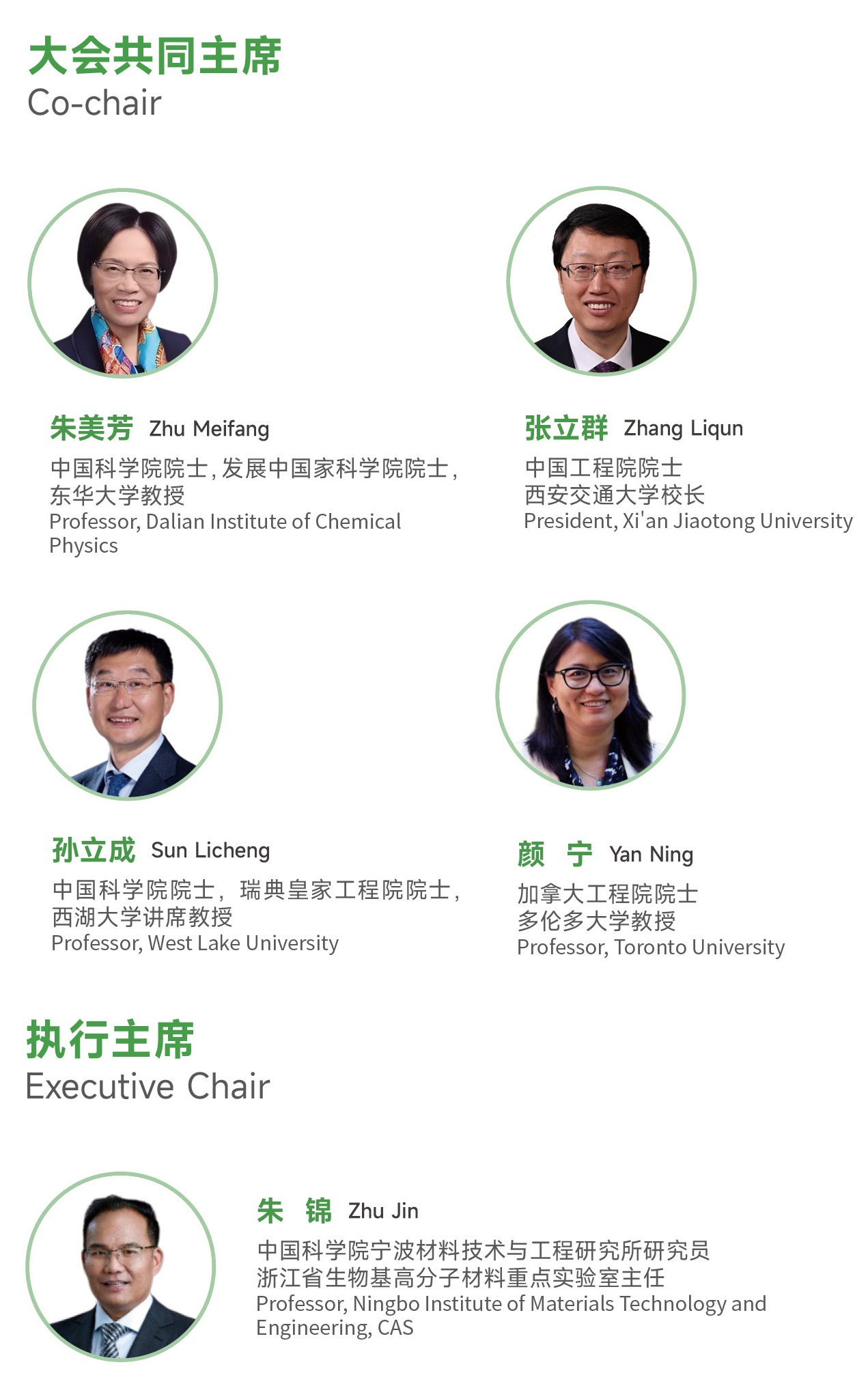

组织机构

主办单位

浙江省生物基高分子材料重点实验室

宁波德泰中研信息科技有限公司(DT新材料)

大会专家顾问团

协办单位

吉林省国科创新孵化投资有限公司

长春市新材料产业知识产权运营服务中心

舟山市投资促进中心

支持单位

中国合成树脂协会生物基与可降解分会

中国合成橡胶工业协会热塑性弹性体分会

生物基材料产业技术创新战略联盟

生物质产业碳中和技术创新联盟

nova institute

韩国生物塑料协会(KBPA)

承办单位

宁波德泰中研信息科技有限公司

论坛板块

AI 赋能未来材料创新发展论坛

5月27日(Day 3),星期二上午

-

09:00

-

09:20

生物制造本质上是“制造业”,中国正在成为全球的生物制造中心之一

廖洁莹,易凯资本合伙人

-

09:20

-

09:40

数据与机理双驱动的分子预训练大模型及其中化学、材料中的应用

曹风雷,上海科学智能研究院研究员

-

09:40

-

10:00

AI 辅助化工新材料研发和生产智慧分析检测落地

龚 雁,镁伽科技能源化工部门市场总监

-

10:00

-

10:30

【先锋对话●Bio-based Talks】未来材料创新发展趋势

对话嘉宾 Sharing Guests

高 航,复星锐正资本董事总经理

Gao Hang, Managing director, Fosun Ruizheng Capital

余 龙,河南省科学院首席科学家,华南理工大学教授,博导 首任中国新加坡国际联合研究院院长

Yu Long, Chief scientist, Henan Academy of Sciences; Professor & PhD supervisor, South China University of Technology

管鹏飞,中国科学院宁波材料技术与工程研究所前沿交叉科学研究中心主任

Guan Pengfei, Director of the Center for frontier interdisciplinary science research, Ningbo Institute of Materials Technology and Engineering, CAS

李 振,苏州聚维元创生物科技有限公司联合创始人

Li Zhen, Co-founder, Suzhou Juwei Yuanchuang Biotechnology Co., Ltd.

李文斌,宁波泰甬汽车零部件有限公司总经理

Li Wenbin, General manager, Ningbo Taiyong Auto Parts Co., Ltd.

-

10:30

-

10:50

生物制造的挑战与 AI 时代下的机遇

杜宇鎏,上海凯赛生物技术股份有限公司研发副主任

-

10:50

-

11:10

基于图神经网络的原子分辨率显微图像的结构多样性探索

许可乐,国防科技大学计算机学院副研究员

-

11:10

-

11:30

高分子材料的分子结构 AI 设计

高 梁,华东理工大学副教授

-

11:30

-

12:00

【先锋对话●Bio-based Talks】AI 在生物基材料领域的应用

对话嘉宾 Sharing Guests

孙 唯,临港集团漕河泾管理公司总经理助理

Sun Wei, Assistant general manager, Caohejing Management Company of Lingang Group

王竞辉,北京微构工场生物技术有限公司技术研发副总裁

Wang Jinghui, Vice president of technology research and development, Beijing Weiguo Workshop Biotechnology Co., Ltd.

李 春,镁伽科技 AI4S 智慧实验室事业部产品总监

Li Chun, Product director of Al4S Intelligent Laboratory Business Division, Megarobo

袁子鹏,上海肆芃科技有限公司副总裁

Yuan Zipeng, Vice president, Shanghai Sipeng Technology Co., Ltd.

刘 潇,上海途深生物科技有限责任公司技术总监

Liu Xiao, Technical director, Shanghai Tushen Biotechnology Co., Ltd.

-

12:00

-

14:00

自助午餐 / 展区参观与交流

青年科学家论坛(二)

5月25日 (Day 1),星期日下午

-

19:00

-

19:10

坡缕石基催化剂的制备及其在有机合成中的应用

吴 尚,西北民族大学教授

报告摘要:

1. 坡缕石的独特性;

2. 坡缕石基催化剂的制备;

3. 坡缕石基催化剂在有机反应中的应用。

-

19:10

-

19:20

多相界面与生物质功能化组装

卢 翊,中国科学院过程工程研究所研究员

报告摘要:

1. 多相界面可有效调控驱动的生物质重组,是突破可再生资源高效转化与绿色制造瓶颈的前沿方向。

2. 报告将表述团队近期在纳米纤维素、纳米甲壳素、以及木材改性方面的最新进展。

3. 利用生物质组分间相互作用稳定非常规结构,是构建绿色高功能材料的新范式与未来发展方向。

-

19:20

-

19:30

基于动态共价化学的生物基交联聚合物

雷泽芃,华南理工大学教授

报告摘要:

发展可持续、高性能的聚合物材料是实现绿色制造与循环经济的关键路径。基于动态共价化学(DCvC)的交联聚合物因其可逆键的引入,展现出优异的可修复性、可重加工性与可回收性,为材料可持续发展提供了新策略。本报告将介绍两类典型的生物基动态交联聚合物体系:蓖麻油基动态聚氨酯(PU)与生物质基动态氰酸酯(PCN)树脂。

-

19:30

-

19:40

纳米纤维素复合材料在环境和食品的应用

邓子龙,同济大学副教授

-

19:40

-

19:50

自组装耐油性天然橡胶材料及荧光天然橡胶材料的构筑及性能研究

黄 蕊,海南大学副教授

报告摘要:

1、自组装方法构筑的耐油性天然橡胶材料

2、柔性单苯环晶体构筑天然橡胶发光基元

3、超分子作用氢键对天然橡胶复合材料性能的影响

-

19:50

-

20:00

基于树枝状MXene异质结的原位催化构筑可持续高强韧聚酯纳米复合材料

丁纪恒,中国科学院宁波材料技术与工程研究所助理研究员

报告摘要:

1. 采用Ti3C2Tx MXene纳米片修饰碳纳米管(CNT),构建出稳定高分散的树枝状异质结构MXene@CNT,该材料兼具缩聚催化、晶体成核与界面增强多重功能。

2. 通过原位催化聚合-热压策略成功制备了生物基MXene@CNT/聚呋喃二甲酸丁二醇酯(PBF)(MCP)纳米复合材料。

3. 基于共价键/氢键/物理互锁构成的多尺度相互作用,MCP表现出优异的综合性能:机械强度(≈101 MPa)、刚度(≈3.1 GPa)、韧性(≈130 MJ/m3)及阻隔性能(O₂ 0.0187 barrer、CO₂ 0.0264 barrer、H₂O 1.57×10⁻¹⁴ g·cm/cm²·s·Pa)均超越多数生物基材料与工程塑料。

4. 具备多重优势:五次循环后强度保持率90%、85%UVA紫外屏蔽能力及显著耐溶剂性。

这种高性能多功能生物基材料为包装与工程领域提供了可持续替代方案,该"催化-界面强化一体化"设计策略为高性能生物基聚酯开发提供了新思路。

-

20:00

-

20:10

生物基聚碳酸酯的设计及构效关系研究

王亚宁,东华大学博士生

报告摘要:

为响应可持续发展,低碳环保等号召,寻找可替代双酚 A 聚碳酸酯的生物基可持续材料,我们开发了一系列基于全异己糖醇

的共聚碳酸酯 (PIsIeCs)。

1. 单体的自催化效应使得分子量大幅提升;

2. 在保证聚碳酸酯强度的同时成功提高了 PIsC 的韧性(屈服强度72.6 MPa,断裂伸长率提高至 74.4%);

3. 刚柔并济单体的引入使得聚碳酸酯在韧性提高的同时仍保持较高的玻璃化转变温度(120.5℃);

4.共聚碳酸酯 PIsIeCs 具有较高的透明性(90-92%)以及生物基含量(72-84%)。

-

20:10

-

20:20

木质素及其衍生物转移加氢制备环醇类化合物的催化剂设计和反应机理的研究

王元杲,中国石油大学(华东)博士生

报告摘要:

1、Ni/CeO2上氧空位的空间分布促进愈创木酚转移加氢合成环己醇;

2、固溶体催化剂协同促进木质素衍生物中C-O键与C=C键的活化与断裂;

3、高浓度愈创木酚转移加氢反应动力学的研究。

HMF-FDCA-PEF产业论坛(二)

5月27日(Day 3),星期二下午

-

14:00

-

14:25

生物基高性能呋喃聚酯合成与功能化研究

王静刚,中国科学院宁波材料技术与工程研究所教授级高工

-

14:25

-

14:50

工业浓度条件下高效催化合成FDCA进展

唐 兴,厦门大学教授,硕/博士生导师

-

14:50

-

15:15

化学生物法升级转化生物质合成 FDCA

何玉财,常州大学教授

-

15:15

-

16:00

【先锋对话●Bio-based Talks】探讨关于FDCA量产、工程化和应用多样化的核心问题

对话嘉宾 Sharing Guests

郭 能,江苏赛瑞克新材料科技有限公司创始人

Guo Neng, Founder, Jiangsu Celluranics New Materials Technology Co., Ltd.

韩长永,宁波华呋新材料科技有限公司董事长

Han Changyong, Chairman of Ningbo Huafu New Materials Technology Co., Ltd.

苏尔寿化工(上海)有限公司

Sulzer Chemtech (Shanghai) Co., Ltd.

刘显伟,杭州云上新材有限公司董事长兼总经理

Liu Xianwei , Chairman and general manager, Hangzhou Cloudichem Innovative Material Co., Ltd.

(更多嘉宾确认中)

(More guests are being confirmed)

关键化学品和材料专场(二)

5月27日(Day 3),星期二上午

-

09:00

-

09:25

非粮生物基衣康酸酯橡胶:助力行业可持续发展

刘 超,山东京博中聚新材料有限公司,分公司总经理

报告摘要:

张立群院士全球首创生物基衣康酸酯橡胶产品,京博中聚和北京化工大学历经十余年的研发,突破工程放大关键核心技术,建设全球首条千吨级生物基衣康酸酯橡胶产业化装置,项目成果经过中国石油和化学工业联合会成果鉴定:成果达到国际先进水平、建议大力推广。京博中聚已经实现鞋材、轮胎、手套等多个领域用产品方案开发, 助力行业绿色可持续发展。

-

09:25

-

09:50

AI助力生物基产品高效生产:分离纯化技术的创新应用

马立新,诺华赛分离技术(上海)有限公司中国区销售总监

-

09:50

-

10:15

合成生物技术在低碳减碳中的作用及实践

张佳龙,珠海金发生物材料有限公司产品线总经理

报告摘要:

分析塑料行业的减碳挑战,描述合成生物技术的发展与优势,介绍金发科技在生物基丁二酸、生物基1,4-BDO上的实践,以及低碳材料的展望。

-

10:15

-

10:45

茶歇/展区参观与交流

-

10:45

-

11:10

生物基尼龙产业现状及发展建议

王晓晨,中石化(上海)石油化工研究院有限公司课题组长

报告摘要:

1、概述生物基尼龙产业整体情况;

2、梳理主要生物基尼龙产品性能特点及应用情况;

3、分析国内外生物基尼龙市场现状及发展趋势;

4、分析国内外生物基尼龙技术发展现状及趋势;

提出生物基尼龙产业存在问题及未来发展方向。

-

11:10

-

11:35

国际可持续发展和碳认证标准要求

吕孟佳,北京绿林认证有限公司,东南亚地区(除印尼外)商务经理

报告摘要:

1.SCS&BGFC 公司的介绍

2.ISCC项目介绍

3.ISCC标准要求

4.ISCC的优势

-

12:00

-

14:00

自助午餐/展区参观与交流

-

14:00

-

14:25

非粮生物质全组分利用制备可降解薄膜

周祚万,西南交通大学特聘教授,化学学院院长

报告摘要:

1.非粮生物质全组分溶解;

2.生物质再生及结构调控;

生物质全组分再生薄膜可控降解。

-

14:25

-

14:50

废旧含棉纺织物的循环利用技术

张 军,中国科学院化学研究所研究员、中科院工程塑料重点实验室主任

报告摘要:

在国家碳中和目标战略和高分子材料可持续发展的大背景下,以纤维素为代表的非粮生物质材料存在极好的发展机遇。发展纤维素的高效、绿色加工新方法是纤维素科学领域极为重要与活跃的领域。离子液体新溶剂的出现为纤维素材料绿色加工和高效转化提供了一个高效、清洁的手段。近年来,以离子液体为溶剂的纤维素加工技术取得重要进展,其中基于离子液体技术的纤维素膜清洁生产新方法已经实现产业化。

另外,离子液体溶剂在低品质纤维素原料的加工和转化中的应用表现出独特的优势,一些在现有纤维素工业上难以应用的低品质纤维素原料,如秸秆、含棉废旧纺织物等,均可以采用离子液体技术加工成性能优良、附加值高的材料,具有良好的工业应用前景。本报告将简要介绍我们在相关领域取得的研究进展。

-

14:50

-

15:15

高效生物基相容剂最新研究进展及其应用

方 超,中国科学院宁波材料技术与工程研究所高级工程师

报告摘要:

1、相容剂的种类及机理介绍;

2、高效生物基酸酐类相容剂最新研究进展及应用;

3、高效生物基环氧类相容剂最新研究进展及应用;

4、接枝类相容剂未来展望。

生物基产业投资与项目路演专场

5月27日(Day 3),星期二下午

-

14:00

-

14:15

棕榈油高效转化及新材料的研发

企业待官宣

-

14:15

-

14:30

玉米秸秆原料化全产业链部署

企业待官宣

-

14:30

-

14:45

新型全生物基海洋可降解材料技术

企业待官宣

-

14:45

-

15:00

软木基皮革开发及应用

企业待官宣

-

15:00

-

15:15

兼容非粮碳源原料的的生物基平台化合物和新材料的研发和产业化

企业待官宣

-

15:15

-

15:30

医用级生物可吸收聚合物的制备与产业化

企业待官宣

-

15:30

-

15:45

1,4-丁二胺的绿色生物合成

企业待官宣

-

15:45

-

16:00

钠离子电池竹基硬炭负极材料及木糖联产

企业待官宣

HMF-FDCA-PEF产业论坛(一)

5月27日(Day 3),星期二上午

-

09:00

-

09:25

从 ( 非粮 ) 葡萄糖大规模工业化制备葡萄糖二酸和 2,5- 呋喃二甲酸

郭 能,江苏赛瑞克新材料科技有限公司创始人 & CEO

-

09:25

-

09:50

报告主题确认中

张 建,中国科学院宁波材料技术与工程研究所研究员、糖能科技首席科学家

-

09:50

-

10:15

可持续材料在化妆品包装领域的机遇(拟)

庄 晨,洽兴包装战略研发总监

-

10:15

-

10:45

茶歇/展区参观与交流

-

10:45

-

11:10

FDCA 原料来源以及解决方案

刘显伟,杭州云上新材有限公司董事长兼总经理

-

11:10

-

11:50

【先锋对话●Bio-based Talks】探讨关于生物基PEF材料开发和应用趋势

对话嘉宾 Sharing Guests

罗 钊,合肥利夫生物科技有限公司 CMO、杭州利夫生物科技有限公司 CEO

张 慧,同辉纺织研发部部长

Zhang Hui, Head of R&D Department, Tonghui Textile

庄 晨,洽兴包装战略研发总监

Zhuang Chen, Strategy research and development director, Qiaxing Packaging

徐 飞,桐昆研究院主管工程师

Xu Fei, Chief engineer, Tongkun Research Institute

杨利平,万凯新材研究院院长

Yang Liping, Director of new materials research institute, Wankai

(更多嘉宾确认中)

(More guests are being confirmed)

-

12:00

-

14:00

自助午餐/展区参观与交流

【可持续应用论坛】生物基皮革专场

5月27日(Day 3),星期二下午

-

14:00

-

14:25

PurewayBio® 创新生物技术如何赋能菌丝体材料的皮革领域应用

李美纯,上海璞然维生物科技有限公司联合创始人,首席运营官

-

14:25

-

14:50

大规模量产与低碳循环:生物基皮革的核心价值

苏 睿,上海贻如生物科技有限公司CEO

-

14:50

-

15:15

超级皮儿:用植纤面料为品牌带来新增长

李卓昆,深圳市朴飞生物科技有限公司联合创始人

-

15:15

-

16:00

【先锋对话●Bio-based Talks】探讨产业链重构:生物基皮革

对话嘉宾 Sharing Guests

王力勇,延锋国际技术中心,资深制造工艺工程师

Wang Liyong, Senior manufacturing process engineer, Yanfeng International Technology Center

李卓昆,深圳市朴飞生物科技有限公司联合创始人

KK, Co-founder, PEELSPHERE

苏 睿,上海贻如生物科技有限公司CEO

Su Rui, CEO, SynMetabio

李美纯,上海璞然维生物科技有限公司联合创始人,首席运营官

Li Meichun, CoFounder, Chief Operating Officer, Pureway Biotechnology Ltd.

【可持续应用论坛】汽车专场

5月27日(Day 3),星期二上午

-

14:00

-

14:25

软木皮革用于汽车内饰部件研发与应用

刘 如,玛斯新材料技术研究(常州)有限公司总经理、中国林业科学研究院木材工业研究所副研究员

1、项目背景:在全球对绿色环保材料需求日益增长的背景下,我们致力于为汽车内饰部件提供创新的生物基材料和行业应用解决方案。通过“以木代皮”的方式,以软木皮革的生物基材料替代传统汽车内饰材料;

2、环保特性:以其柔韧性、耐用性和环保特性的软木作为原料,成为理想的内饰材料;

3、涂层复合:通过环保的涂层复合技术,实现高耐光同时赋予表面良好的理化性能;

4:一体成型:通过模内注塑工艺,实现内饰部件的一体化工艺,提高生产效率和产品一致性;

5、产品应用:已形成了一系列软木基复合材料产品,如鞋垫;

6、市场开拓及潜力:已经与多家知名车企及部件厂商企业建立联系,通过B-B以及B-C多渠道,进行营销。公司已完成多个试点项目,并正在进行材料的车规级测试,预计将在未来12个月内实现大规模应用。

-

14:25

-

14:50

天然纤维技术

周楠婷,上海蔚来汽车有限公司汽车材料主任工程师

-

14:50

-

15:15

新型生物基聚碳酸酯DURABIO的特征与应用

闫家林,三菱化学(中国)管理有限公司 DURABIO中国区主要技术负责人

-

14:40

-

15:15

“碳”寻绿色发展路径,打造100%可持续材料轮胎

薛天翔,固特异轮胎管理(上海)有限公司高级科学家,亚太区新材料研发负责人

演讲摘要:

固特异简介

可持续发展与电动汽车轮胎的现状与前景

固特异的可持续发展之路

固特异可持续材料轮胎进展

-

15:40

-

16:10

茶歇 / 展区参观与交流

-

16:10

-

16:35

阿朗新科的可持续发展路线图

陈民杰,阿朗新科高性能弹性体(常州)有限公司高级技术经理

-

16:35

-

17:20

【先锋对话●Bio-based Talks】 革新与挑战:汽车行业的绿色转型趋势与生物基材料的准入门槛

李菁华,中国第一汽车集团有限公司研发总院 材料与轻量化研究所 高级主任; 周楠婷,上海蔚来汽车有限公司汽车材料主任工程师; 刘 如,玛斯新材料技术研究(常州)有限公司总经理、中国林业科学研究院木材工业研究所副研究员; 化丹丹,郑州中远企业集团应用市场经理;

-

18:30

-

20:00

生物基产业欢迎晚宴

国际合作专场

5月26日-27日,星期一-二

-

14:00

-

14:25

芬兰-引领可持续发展与创新

归盈颖,芬兰投资署高级投资顾问

-

14:25

-

14:50

欧洲生物基工业的挑战和机遇以及投资机会

Lars Börger, nova institute, Co-CEO

-

14:50

-

15:15

韩国生物塑料产业的挑战

陳仁柱,韩国生物塑料协会秘书长

-

15:15

-

15:40

(TBD)Brewed Protein™材料:材料和产品开发中的应用

関山和秀,思百博执行CEO

报告摘要:

思百博成立于 2007 年,总部位于日本山形,是一家专注于生物科技创新的创业公司。公司致力于研发推动可持续发展的突破性解决方案。受自然多样性和循环性的启发,思百博开发了 Brewed Protein™ 材料平台——一种全新的材料解决方案。通过精准发酵技术,思百博在分子层面设计蛋白质,从而生产出可根据特定需求定制的多功能材料。这一创新解决方案为服装、食品、汽车等多个行业的可持续高性能材料开辟了全新可能。思百博携手合作伙伴,不断拓展 Brewed Protein™ 材料的多元化应用,共同迈向更加可持续的未来。我们的愿景是推动循环经济,最大限度减少环境影响,并携手共建一个包容、公平、可再生的世界。

-

15:40

-

16:10

茶歇/展区参观与交流

-

16:10

-

16:35

立足泰国,面向东盟—中国科学院曼谷创新合作中心科技出海合作实践

杨子锋,中国科学院曼谷创新合作中心项目总监

-

16:35

-

17:00

加速向生物经济转型:荷兰的政策与创新

李弘艺,荷兰王国驻广州总领事馆科技官员,荷兰科技办公室

-

17:00

-

17:25

利用可替代生物质制备乳酸

Jan Pieter van Tilburg, CEO, Nature’s Principles

-

18:30

-

20:00

生物基产业欢迎晚宴

【可持续应用论坛】包装专场

5月26日(Day 2),星期一下午

-

14:00

-

14:25

包装与环境领域最新政策动态及应对措施

冯清正,中国出口商品包装研究所副总工程师

演讲摘要:

1、包装与环境领域政策概览

2、欧盟包装与环境技术法规介绍

3、包装行业应对举措和建议

-

14:25

-

14:50

绿色智慧·解锁可持续包装未来生态

王传龙,四川省宜宾普拉斯包装材料有限公司副总经理、研究院院长

五粮液旗下,国内大型塑胶包装生产企业

-

14:50

-

15:15

欧盟包装法规进程及影响分析

张安,生物基行业专家,德国nova 研究所(nova-Institut) 中国项目负责人

欧洲生物经济顶尖研究机构

-

15:15

-

15:40

合成生物技术赋能PHA新材料产业化落地

王竞辉,北京微构工场生物技术有限公司技术研发副总裁

-

15:40

-

16:10

茶歇/展区参观与交流

-

16:10

-

16:35

绿色包装创新助力自有品牌可持续发展

张涛,麦德龙商业集团高级包装研发经理

报告摘要:

1. 自有品牌包装特点

2. 麦德龙包装可持续发展战略

3. 绿色包装案例

-

16:35

-

17:20

【先锋对话●Bio-based Talks】可持续包装应用进展的挑战与机遇?

拟邀:国际机构、产业协会、终端品牌、可持续包材开发和解决方案企业

主持人

The Moderator

冯清正,中国出口商品包装研究所副总工程师

Feng Qingzheng, Deputy chief engineer, China Export Commodities Packaging Research Institute

对话嘉宾

Sharing Guests

王小慧,华南理工大学教授,先进造纸与纸基材料全国重点实验室主任

Wang Xiaohui, Professor, South China University of Technology

张 安,生物基行业专家,德国 nova 研究所(nova-Institut)中国项目负责人

Zhang Ann, Expert in the bio-based industry & Head of the China program, nova-Institut

宋 宇,中科国生(杭州)科技有限公司副总裁

Song Yu, Vice president, Zhongke Guosheng (Hangzhou) Technology Co., Ltd.

-

18:30

-

20:00

生物基产业欢迎晚宴

【可持续应用论坛】生物基纤维-面料&非织造布专场

5月26日(Day 2),星期一 下午

-

09:00

-

09:20

非粮生物基化学纤维及原料开发

李增俊,中国化学纤维工业协会原总经济师,生物基纤维分会、丙纶分会、氨纶分会常务副会长

-

09:20

-

09:40

聚乳酸纤维技术与应用新进展

鲁士君,深圳光华伟业股份有限公司 副总经理、易生新材料(苏州)有限公司 总经理

-

09:40

-

10:00

PLA复合熔喷无纺布开发

张会良,中国科学院长春应用化学研究所研究员

-

10:00

-

10:20

Sorona®生物基PTT纤维产业化创新实践

胡腾蛟,上海华峰瑞讯生物材料有限公司研发总监

-

10:20

-

10:50

茶歇/展区参观与交流

-

10:50

-

11:10

生物可降解涤纶纤维

李家旭,浙江恒逸集团有限公司高级工程师

-

11:10

-

11:30

先锋对话(圆桌交流):生物基纤维赛道有哪些新方向?产业挑战在哪里?

中国科学院长春应用化学研究所、扬州惠通生物新材料有限公司、浙江同辉纺织股份有限公司、海华峰瑞讯生物材料有限公司

对话嘉宾 Sharing Guests

李增俊,中国化学纤维工业协会原总经济师,生物基纤维分会、丙纶分会、氨纶分会常务副会长

Li Zengjun, Former chief economist, China Chemical Fiber Industry Association; Executive Vice President, Bio-based Fiber Branch, polypropylene fiber branch and Spandex Branch

张会良,中国科学院长春应用化学研究所研究员

Zhang Huiliang, Researcher, Changchun Institute of Applied Chemistry, CAS

刘 雄,扬州惠通生物新材料有限公司总经理

Liu xiong, General manager, Yanghzou Huitong Biomaterials Co., Ltd.

张 慧,浙江同辉纺织股份有限公司研发部部长

Zhang Hui, Head of R&D Department, Tonghui Textile

胡腾蛟,上海华峰瑞讯生物材料有限公司技术总监

Hu Tengjiao, Technology director,Huafon Covation Biomaterials Shanghai Co., Ltd.

-

12:00

-

14:00

自助午餐/展区参观与交流

关键化学品和材料专场(一)

5月26日(Day 2),星期一下午

-

14:00

-

14:20

纳米纤维素造纸应用新进展

姚献平,杭州市化工研究院院长、国家造纸化学品工程技术研究中心主任

报告摘要:

简要介绍了纳米纤维素在造纸应用中的主要特性与作用原理;主要介绍了纳米纤维素在白板纸、文化用纸、生活用纸以及特种纸中的应用新进展与案例分享,并提出了建议与产业化展望。

-

14:20

-

14:40

苏尔寿应用于生产 PLA 和 PCL 的技术

Alex Battu,苏尔寿全球许可业务总监

报告摘要:

向更环保的传统塑料替代品的转变不仅依赖于材料科学的创新,也依赖于能够实现高效高质量生产的强大且可扩展的技术。苏尔寿化工技术公司凭借其在连续聚合领域的长期专业知识以及数十年的生物基工艺研发经验,打造了用于生产可生物降解和生物基聚酯的完整技术组合,例如聚乳酸 (PLA)、聚乙醇酸 (PGA)、聚己内酯 (PCL) 和聚呋喃甲酸乙二醇酯 (PEF)。这些聚酯采用开环聚合技术合成。

我们专有的设备设计实现了卓越的操作灵活性,同时确保了最佳的传热和传质性能,从而实现了稳定的产品质量和高效的工艺效率。本次研讨会将重点介绍我们工艺技术的最新进展,尤其关注可扩展性、模块化部署以及与上游生物中间体的集成。

此外,苏尔寿化工技术公司通过与全球工业合作伙伴的成功合作,凭借市场吸引力,开发了终端生物聚合物应用,并正在将这些成果转化为各行各业的实际效益。

-

14:40

-

15:00

生物基烯烃研究进展及前景

吴 韬,宁波诺丁汉大学首席教授,浙江省有机废弃物转化及过程强化技术重点实验室主任

-

15:00

-

15:20

万华低碳弹性体材料赋能客户可持续发展

陈子雄,万华化学集团股份有限公司市场开发经理

报告摘要:

1、弹性体材料在鞋材领域应用;

2、TPU弹性体:高性能与可持续的平衡应用开发;

3、尼龙12弹性体:轻韧结合,赋予鞋材新的动力;

4、POE弹性体:材料共混,拓展鞋材应用;

5、绿色循环科技赋能全链产品制造。

-

15:20

-

15:40

新型生物基造纸化学品与生物质材料

王小慧,华南理工大学教授,先进造纸与纸基材料全国重点实验室主任

-

15:40

-

16:20

茶歇/展区参观与交流

-

16:20

-

16:40

“三非”创新技术生产恒碳Biebl® 1,3-丙二醇及其在可降解化妆品包材开发中的应用

张炽坚,广东恒碳科技有限公司总经理

报告摘要:

1、恒碳Biebl™ 1,3-丙二醇生产创新技术介绍;

2、生物基1,3-丙二醇副产品综合利用策略;

3、生物基1,3-丙二醇在可降解化妆品包材开发中的应用介绍。

-

16:40

-

17:00

秸秆糖生物合成柔性生产平台助力生物制造新质生产力

李 振,苏州聚维元创生物科技有限公司联合创始人

报告摘要:

1、 非粮路线的重要性;

2、 非粮技术路线的技术难点;

3、 聚维元创在非粮生物基领域的工作;

4、未来展望。

-

17:00

-

17:20

可持续热固性树脂—从生物基到可控化学降解

刘小青,中国科学院宁波材料所研究员

报告摘要:

发展环境友好高分子材料是实现“碳达峰,碳中和”的重要手段之一。本报告将讲述我们在可持续环氧树脂及复合材料领域的研究工作,具体包括高性能生物基环氧树脂、生物基环氧树脂阻燃剂,尤其是可产业化的降解环氧树脂技术。

-

18:30

-

20:00

生物基产业欢迎晚宴

【全体大会】生物基产业宏观论坛

5月26日(Day 2),星期一上午

-

08:50

-

09:00

开幕式

致辞嘉宾

-

09:00

-

09:15

2025(第三届)新叶奖颁奖典礼

创新材料奖

创新应用奖

创新行业解决方案奖

最具商业价值奖

获奖企业即将揭晓!

-

09:15

-

09:55

向绿而行—HMF电催化氧化还原

孙立成,中国科学院院士,西湖大学讲席教授

孙立成,中国科学院院士,中国化学会会士、欧洲化学会会士(Chemistry Europe Fellow)、英国皇家化学会会士(FRSC),人工光合作用领域专家。曾任瑞典皇家工学院分子器件讲席教授,大连理工大学—瑞典皇家工学院分子器件联合研究中心主任。在德国马普辐射化学研究所、柏林自由大学、斯德哥尔摩大学和瑞典皇家工学院工作28年后,于2020年初全职回国加盟西湖大学,现任西湖大学讲席教授、西湖大学人工光合作用与太阳能燃料中心主任、浙江省首批顶尖人才、能源与碳中和浙江省实验室(既白马湖实验室)首席科学家、国家自然科学基金委员会化学科学部第九届专家咨询委员会委员。孙立成教授长期从事太阳能燃料与太阳能电池前沿领域应用基础研究,在人工光合作用关键科学问题即高效水氧化催化剂设计合成、氧-氧键形成机理、光电催化水分解制氢功能器件设计、光电催化二氧化碳/氮气还原、阴离子交换膜电解水制氢、新型钙钛矿太阳能电池空穴传输材料设计与制备、电催化HMF氧化/还原制备FDCA/DHMF连续化生产绿色工艺等领域具有深厚研究基础。在化学及能源材料学术期刊上发表SCI论文及评述800余篇,论文他引70000余次,h-index为138,连续多年入选全球“高被引学者”。曾任德国Wiley期刊ChemSusChem编委会主席、Journal of Energy Chemistry副主编,现任ACS Artificial Photosynthesis副主编。曾获瑞典皇家科学院沃尔玛克奖、Ulla och Stig Holmquist 有机化学奖, Arrhenius奖章, 中华人民共和国国际科技合作奖等国际奖项及学术荣誉。

-

09:55

-

10:25

生物基高分子材料研究进展

朱 锦,中国科学院宁波材料技术与工程研究所研究员,浙江省生物基高分子材料重点实验室主任

朱锦,中科院宁波材料技术与工程研究所研究员,博士生导师,2001年在美国马凯特(Marquette) 大学获得博士学位,2001-2003年在美国康奈尔(Cornell) 大学做博士后,其后曾任职于美国多家企业。2010入选中科院“百人计划”,2012入选第八批中组部“国家特聘专家”,曾获全国优秀科技工作者、 浙江省“十佳优秀科技工作者”、中国产学研合作创新成果奖、中国林产工业创新奖等。2009年8月回国后成立生物基高分子材料研究团队。主要从事生物基高分子材料研究与开发工作。 现任浙江省生物基高分子材料技术与应用重点实验室主任。目前正在主持国家重点研发计划“低成本高性能生物基聚酯和聚碳酸酯的制备与产业化”和国家自然基金委联合重点基金“含刺激分解单元的高性能生物可降解高分子材料研究”。带领团队在国内率先实现了“大豆基无醛木材胶粘剂”、“耐热聚乳酸发泡材料”、“禾塑复合材料” 、“高Tg透明聚酯” 和“呋喃二甲酸及聚酯”等多项成果实现产业化,并产生显著经济和社会效益。目前担任《SusMat》和《Journal of Renewable Materials》副主编, 《高分子通报》、《Chinese Journal of Polymer Science》、《Composites Part B》和《European Polymer Journal》编委。已发表研究论文360多篇,被引用17000多次。已获得中国、美国授权专利170多项。曾编著《生物基高分子材料》和《生物基呋喃聚酯》两本书,由科学出版社出版。

-

10:25

-

10:35

浙江省舟山市整体投资环境介绍

任益穗,浙江省舟山市投资促进中心副主任

-

10:35

-

11:05

茶歇/展区参观与交流

-

11:05

-

11:35

生物基可降解橡胶产业化进展及其应用

王 朝,华南理工大学教授,黄埔绿色先进材料技术研究院执行院长

王朝,华南理工大学材料学院教授,黄埔绿色先进材料技术研究院执行院长。自2009年一直专注于生物基合成橡胶领域,主要从事生物基可降解橡胶的分子结构设计、工程化和应用开发。

开发出我国原创的生物基及可生物降解的合成橡胶新品种,突破其万吨级聚合技术和纳米复合技术,发展出可降解橡胶制品新赛道,正在推动解决全球废弃橡胶制品特别是每年600万吨轮胎磨屑的环境污染难题,实现国际引领。

-

11:35

-

12:05

“十五五”石化产业发展趋势探讨--可持续发展之道

庞广廉,中国石油和化学工业联合会党委常委、外资委主席兼秘书长

庞广廉

中国石油和化学工业联合会党委常委、副秘书长

国际交流与外企委员会主席兼秘书长

中国石油和化工行业国际产能合作企业联盟秘书长

国家化工对外经济合作中心 主任

普凯源国际石化技术发展(北京)有限公司 总经理

世界塑料理事会管理委员会成员

AEPW(终结塑料废弃物联盟)中国工作组联席主席

庞广廉,现任中国石油和化学工业联合会党委常委、副秘书长,国际交流和外企委员会秘书长,中国石油和化工行业国际产能合作企业联盟秘书长,国家化工对外经济合作中心主任,对外经济贸易大学、上海应用科技大学等兼职教授,高级国际商务师,国际营销专家。

-

12:05

-

14:00

自助午餐 / 展区参观与交流

青年科学家论坛(一)

5月25日(Day 1),星期日下午

-

14:00

-

14:10

高性能与功能型生物基光固化材料的绿色制备、性能及应用

刘承果,南京林业大学教授

报告摘要:

利用天然可再生的生物质资源制备光固化材料,对生物质资源的高值化利用与光固化料产业的可持续发展来说均具有十分重要的意义。生物基光固化材料研究中存在热/力学性能不足、难以自修复与回收加工、高性能与易回收难以兼得、制备方法污染严重等诸多问题。针对这些问题,我们以植物油、天然酚等为起始原料,结合绿色合成方法、动态键化学等,构建了系列高性能、可自修复、可回收加工的光固化材料,应用于涂料、3D打印等领域,并揭示了材料的构效关系、自修复/回收机制等。研究工作不但可提供具有潜在应用价值的生物基光固化树脂产品,而且可为该类材料的设计及应用提供新思路和新途径。

-

14:10

-

14:20

胆酸聚酯“类抗菌肽”

贾永光,北京师范大学研究员

报告摘要:

面对越来越严重的细菌耐药性,抗菌肽被誉为最有希望的新一代抗生素,然而抗菌肽固有的高成本、低活性、易酶解的缺陷,限制其在临床上的应用。胆酸是一种由胆固醇衍生而来的内源性有机酸,对于维持哺乳动物体内的脂质吸收运输和调控免疫反应起到重要作用,其分子结构呈现出与抗菌肽类似的独特面两亲特征。本研究中以面两亲结构仿生的设计思路,通过无催化缩聚策略将面两亲性的小分子胆酸转化为面两亲的胆酸聚酯“类抗菌肽”高分子。该“类抗菌肽”不但可降解且易于作为医疗器械涂层使用。与常用抗生素青霉素G相比,“类抗菌肽”具有快速杀菌能力和不易诱导发展耐药菌的优点,同时还克服了抗菌肽热稳定性差、易酶解的缺点。在小鼠创面感染耐甲氧西林金黄色葡萄球菌的实验中,胆酸聚酯“类抗菌肽”表现出了最好的体表抗菌活性、较快的伤口愈合速度以及良好的组织相容性。

-

14:20

-

14:30

拉曼在线分析 : 助力生物过程可视化和工艺优化

阮银兰,桂林电子科技大学研究员

报告摘要:

过程分析技术(PAT)是生物制药和合成生物学产品产能提升和智能制造的关键手段,拉曼光谱是一种分子指纹谱分析技术,已日渐成为PAT所使用的基本传感工具。本报告将介绍拉曼技术在细胞培养和发酵工艺中的在线分析及反馈控制应用,以及我们最新的克服背景荧光干扰的时间门控拉曼检测技术和空芯光纤拉曼增强技术的研发进展。

-

14:30

-

14:40

生物质基多元酸及可循环聚酯材料

呼延成,中国矿业大学教授

报告摘要:

1. 多元酸是重要的化工原料,可以制备聚酯材料,广泛用于生产生活的各个行业。充分利用生物质及其衍生物制备多元酸,有可能提供一条不依赖化石资源的技术路线。

2. 以果糖为原料,固体酸催化下,可以一步获得呋喃二甲醛。继续与丙二酸酯反应生成呋喃基不饱和酸酯,通过调控后续加氢深度,可以选择性获得不同骨架的二元羧酸酯,包括呋喃基二元酸、四氢呋喃基二元酸与辛二酸。

3. 以乙酰丙酸为原料,经过脱水反应获得当归内酯,再与丙烯酸酯反应可得到加成产物,最后再加氢脱氧,可以选择性获得对称的甲基庚二酸。该单体可以与乙二醇和对苯二甲酸进行共聚,生产共聚酯,有部分取代石油基PBAT聚酯的潜力。

-

14:40

-

14:50

基于胆汁酸的分子水凝胶制备及形成机理研究

张 猛,北京师范大学副教授

报告摘要:

1. 以天然生物分子胆汁酸及其衍生物为主要研究对象,深入研究了分子凝胶形成过程中的物理化学相互作用,揭示了凝胶剂分子结构与其成凝胶性能之间的联系;

2. 提出了临界微溶条件决定的分子凝胶形成机理。

3. 研究成果为分子凝胶的设计和制备提供一套理论指导模型,对于发展新型功能分子凝胶体系以及推动分子凝胶的应用具有重要科学意义。

-

14:50

-

15:00

食品加工副产物的高值循环利用及其在活性包装中的应用

黄舒婷,江南大学校聘副教授

报告摘要:

1.针对典型的食品加工副产物进行成分分析和微纳材料的提取。

2.利用提取的微纳材料进行功能性改性。

3.探究其在活性包装中的应用。

-

15:00

-

15:10

乙酰丙酸基可回收热固性树脂

刘艳林,中国科学院宁波材料技术与工程研究所副研究员

报告摘要:

1、乙酰丙酸基可回收环氧树脂;

2、乙酰丙酸基可回收聚脲。

-

15:10

-

15:20

新型生物基聚酯材料的制备和性能研究

庞成才,天津理工大学教授

报告摘要:

(1)为获得同时具有生物降解性能以及闭环回收的热塑性聚酯,我们合成了含有酰亚胺结构的均聚酯,均聚酯的Tg值在59-136 ℃之间,力学强度接近或者超过石油基聚如PET。这些材料具有良好的降解能力,同时可以实现闭环的物理和化学回收。重复加工5次后,材料的力学强度没有明显下降。

(2)从柠檬酸出发合成了一种高刚性的四乙烯基化合物(4V)。4V 进一步经历了全甲基化反应得到了刚性和热稳定的四乙烯基化合物(4MV)。通过无溶剂硫醇 - 烯偶联,开发了两个系列的网络。4V 系列表现出相似的玻璃化转变温度(Tg)值,突出了 4V 的显著刚性。与基于相同硫醇的 4V 类似物相比,4MV 系列表现出更高的热稳定性、Tg 值和机械性能。所有聚合物都获得了在可见光区域(> 500nm)具有约 90%透射率的高透明无色薄膜。这些材料显示出适中的折射率(n),在 1.5075-1.5779 范围内。因此,这些材料在多种应用中具有巨大潜力,例如发光二极管的封装树脂、抗反射涂层的光学材料和显示设备。

-

15:20

-

15:30

反应挤出定构高性能生物可降解包装材料

吴 枫,昆明理工大学副教授

报告摘要:

1. 通过简单的反应挤出加工策略,一步化定构具有优异强韧平衡力学性能的生物可降解共混体系;

2. 通过界面增容策略提升生物可降解高分子的水汽阻隔性能,定构化加工制备具有优异光学透明性和优异阻隔性能的生物可降解薄膜;

3. 高韧性、高阻隔生物可降解材料的应用与市场评价。

-

15:30

-

16:00

茶歇 & 现场交流

-

16:00

-

16:10

生物基多功能高分子新材料的构筑——阻燃、抗菌、抗氧化功能的设计

杨伟军,江南大学副教授

报告摘要:

利用木质素平台化合物如香草醛、丁香酚作为原料,通过分子结构设计,合成了一系列本征阻燃、抗氧化、抗菌功能高分子新材料(如环氧树脂、聚氨酯、聚硫醚/氨酯等)。

1、本征抗菌抗氧化聚氨酯的抗菌效率可达99.9%,抗氧化效率达到92%以上,耐热氧化性能优异;

2、环氧树脂、聚氨酯、聚硫醚/氨酯(薄片、泡沫等)阻燃达到V0等级,LOI>27%,含磷量低至0.5%;

3、可自修复、可重加工、可降解回收利用。

-

16:10

-

16:20

全水相中固体酸催化非粮生物质的高效转化

冯成启,中国科学院宁波材料技术与工程研究所助理研究员

报告摘要:

1.纤维素定位、结构特征;

2.现阶段纤维素水解难点;

本研究组中纤维素水解的发展及成果。

-

16:20

-

16:30

生物基聚酯形状记忆高分子的设计与制备

王考进,北京师范大学讲师

报告摘要:

1.形状记忆高分子材料(SMPs)是一种在一定的条件下改变其初始形状并固定后(临时形状),在外界刺激下(如热、光、电、磁、微波、超声、溶剂、金属离子、酸碱度等)可恢复到其初始形状的智能高分子材料。双向可逆形状记忆高分子材料克服了单向形状记忆行为不可逆性的局限,极大扩展了其应用范围。目前,形状记忆高分子材料的生物相容性普遍较差。

2.我们首先基于简便的方法合成了生物基的多重形状记忆聚合物,又开发出了驱动温度可调的双向可逆形状记忆聚合物,在此基础上加入聚多巴胺光热纳米粒子,开发出了光响应的可行走的机器人以及人工肌肉。通过加入聚集诱导发光基团,开发出了可发光的双向可逆形状记忆聚合物,又通过加入具有分子内扭曲电荷效应的AIE分子,开发出了可同时可逆变形变色的聚合物。以上这些智能材料均具有较好的生物相容性和可降解性能。

3.这些开发的智能高分子材料有望被应用到生物医用、智能仿生及航空航天等领域。

-

16:30

-

16:40

木质素温和解聚体系的构建及反应机理研究

曾 旭,华侨大学讲师

报告摘要:

1、木质素碱金属醇盐催化解聚;

2、木质素常温电催化还原解聚;

3、木质素常温电催化氧化解聚。

-

16:40

-

16:50

生物质基抗菌食品包装薄膜的设计与应用研究

刘 群,集美大学副教授

报告摘要:

近期关于生物质基抗菌食品包装材料的两个工作进展报告:

1.竹笋壳纳米纤维-肉桂醛/壳聚糖乳液制备防水抗菌食品包装膜

2.茶渣水热碳化液/聚乙烯醇复合食品包装薄膜

-

16:50

-

17:00

生物基超支化聚合物的增强增韧与循环利用

张俊珩,中南民族大学副教授

报告摘要:

1:非粮生物基超支化环氧树脂的合成方法

2:超支化聚合物增强增韧机理及界面增强机制

3:超支化环氧树脂高值循环回收利用机制

-

17:00

-

17:10

杜仲橡胶高效提取及其特种功能材料研发

朱铭强,西北农林科技大学教授

-

17:10

-

19:00

休息时间

特别鸣谢单位

新品展示企业 | 一句话介绍 |

万华化学集团股份有限公司 | 全球化化工新材料头部企业 |

三菱化学(中国)管理有限公司 | 全球化工巨头 |

苏尔寿化工(上海)有限公司 | 全球流体工程领域头部企业 |

扬州惠通科技股份有限公司 | 世界知名的国际工程公司 |

合肥利夫生物科技有限公司 | PEF & FDCA 全球领军企业 |

苏州聚维元创生物科技有限公司 | 秸秆源生物基丁二酸产业化企业 |

中科国生(杭州)科技有限公司 | HMF-FDCA-PEF全产业链代表性企业 |

思创绿源(深圳)环保科技有限公司 | 全生物环保包装突破性创新企业 |

江苏赛瑞克新材料科技有限公司 | 葡萄糖二酸-FDCA-聚酯等产品全产业链企业 |

河南骐业科技发展有限公司 | 秸秆糖+高值产品的非粮生物基材料企业 |

中科柏易金(郑州)新能源科技有限责任公司 | 生物质乙二醇、生物基1,3-丙二醇国际技术领先企业 |

玛斯新材料技术研究(常州)有限公司 | 软木皮革明星企业 |

广东恒碳科技有限公司 | 恒碳Biebl®生物基1,3-丙二醇生产企业 |

杭州云上新材有限公司 | 呋喃类生物基材和含氟电子化学品生产企业 |

苏州亚科科技股份有限公司 | 非粮生物基FDCA、PEF产品开发企业 |

安吉兴能生物基新材料股份有限公司 | 竹基生物基多酚类产品开发及应用企业 |

浙江糖能科技有限公司 | 生物基呋喃新材料创新引领者 |

邓州市金碧生物材料科技有限公司 | 国内唯一可提供聚乳酸耐高温发泡技术工艺改性原料及制品的供应商 |

河南正通食品科技有限公司 | 生物质来源的异山梨醇及其衍生助剂产品主要企业 |

宁波华呋新材料科技有限公司 | 2,5-呋喃二甲酸(FDCA)开发企业 |

泰安羽时生物科技有限公司 | 淀粉基塑料产品知名企业 |

南京泓威生物材料有限公司 | 聚乳酸功能改性新锐企业 |

上海聚友化工有限公司 | 知名高分子聚合工程实施的高新技术企业 |

BETA实验室 | 生物基含量检测领域专家 |

北京绿林认证有限公司 | ISCC认证和RSB认证服务专业企业 |

华测认证有限公司 | 第三方检测与认证服务的开拓者和领先者 |

吉林省产品质量监督检验院 | 拥有“国家生物基产品质量检验检测中心 (吉林)” |

广东宏拓仪器科技有限公司 | 一站式解决材料力学性能等检测难题的仪器专家 |

杭州中旺科技有限公司 | 粘度检测高端解决方案企业 |

山东埃尔派粉体科技股份有限公司 | 国际知名功能粉体设备企业 |

诺华赛分离技术(上海)有限公司 | 知名分离纯化技术与合成技术工程公司 |

南京膜材料产业技术研究院有限公司 | 特种分离膜材料、膜装备供应商 |

珠海市长陆工业自动控制系统股份有限公司 | 智能工厂自动化与信息化综合解决方案企业 |

上海霍桐实验仪器有限公司 | 知名实验室反应釜等解决方案制造商 |

北京托摩根生物科技有限公司 | 专业的生物降解仪生产企业 |

奥斯龙泵业江苏有限公司 | 专业从事泵类产品生产经营企业 |

碧普仪器(浙江)有限公司 | 生物降解领域智能化检测专家 |

郑州沃华机械有限公司 | 国内专业的熔体泵制造商 |

武汉瑞鸣实验仪器制造有限公司 | 微型挤出机/注塑机专业制造商 |

安徽科幂仪器有限公司 | 知名实验室反应釜等解决方案制造商 |

上海莱北科学仪器有限公司 | 反应釜、反应系统集成装置优质供应商 |

无锡华辰机电工业有限公司 | 知名水下切粒系统解决方案供应商 |

上海岩征实验仪器有限公司 | 实验室反应器基反应装置领军企业 |

亚波光子(深圳)科技有限公司 | 知名拉曼生物过程分析仪企业 |

信安诺医药科技(上海)有限公司 | 微生物培养发酵罐设备企业 |

吉林省国科创新孵化投资有限公司 | 中科吉林科技产业创新平台运营方 |

上海博师通电器有限公司 | 生物基材料降解测试设备领域的领先企业 |

上海霍卫技术装备有限公司 | 聚乳酸全流程工艺技术及关键设备的设计及供货商 |

Enzidia(丹麦) | 以先进的酶加速科技,赋能生物制造革命 |

环霆科技(宁波)有限公司 | 完全可降解材料及其应用产品开发的领先企业 |

山东京博中聚新材料有限公司 | 生物基衣康酸酯橡胶创新企业 |

芬兰国家商务促进局 | 生物基企业出海欧洲的“护航舰队” |

(更多赞助企业确认中)

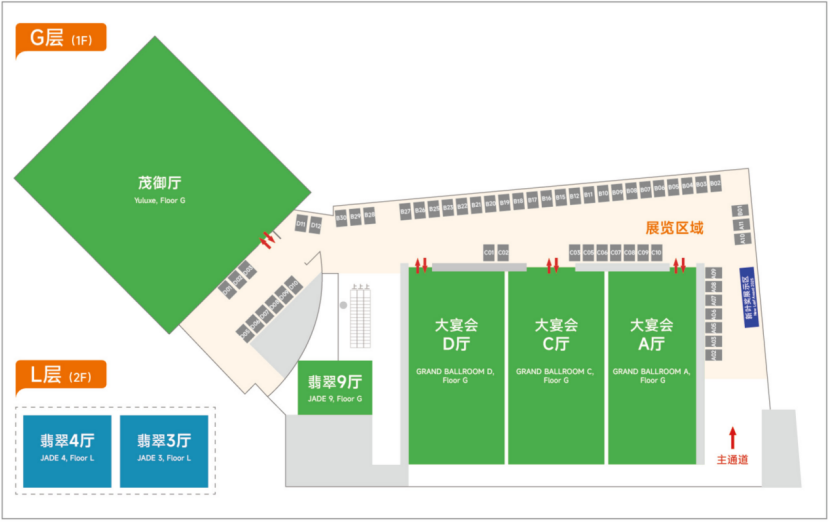

展位与会场分布

同期特色活动

Bio-based 2025 将基于产业不同需求,同期举办精彩纷呈的交流与对接活动。↓↓↓

(一)生物基产业战略发展研讨会

未来十年,生物基产业发展走向如何?“生物基产业战略发展研讨会”将为行业权威把脉,邀请行业头部企业高层共同建立生态链与合作平台。

(二)终端品牌需求对接专场

为促进产业上下游交流合作,我们将收集终端品牌的材料需求,将于大会现场同期举行终端需求对接会,为您打开更多合作新商机!

点击了解已官宣品牌需求,欢迎对接:

(三)专家“坐诊”:技术合作交流专场

为助力行业研发和选品过程中的人才合作、技术合作,大会现场同期举行“专家“坐诊””活动,欢迎对接生物基产业化知名大咖,大咖团即将揭晓!

(四)科技成果对接专场

企业可持续发展转型升级的机遇,更是新时代经济发展的重要动力之一。哪里找生物基科技创新项目?如何有效交流?

对此,大会将设置特色活动「科技成果展示与对接」,公开征集100个生物基领域具备商业化基础的创新成果和项目,于现场公开展示。方向聚焦生物质能源、生物基化学品、材料产品开发及创新应用,欢迎科研院所、创新企业报名!